OMRON E2EHSensors/ Proximity Sensors/Cylindrical

OMRON E2EH Sensors

- E2EH Proximity Sensor Ideal for High Temperatures and Cleaning Processes/Lineup

- E2EH Proximity Sensor Ideal for High Temperatures and Cleaning Processes/Catalog

- E2EH Proximity Sensor Ideal for High Temperatures and Cleaning Processes/Dimensions

- E2EH Proximity Sensor Ideal for High Temperatures and Cleaning Processes/Specifications

- Purchase the OMRON E2EH Cylindrical

OMRON E2EH Dimensions

/Images/l_1866-25-118696-198x198.jpglast update: October 15, 2012

SUS316L Body, IP69K Protection, Resistant to High Temperatures and Detergents

Improved resistance to detergents and rusting

Applicable to 120°C (with DC 3-wire connection)

(Heat resistance verified to 1,000 hours.)

Resists typical detergents and disinfectants used in the food industry

Water resistant under high-temperature, high-pressure cleaning based on DIN 40050-9.

(Pressure: 8,000 to 10,000 kPa, Water temperature: 80°C, For 30 s at all angles)

last update: October 15, 2012

Purchase the OMRON Cylindrical Please fill in the following

If you have just landed here, this product OMRON E2EH Sensors,Sensors is offered online by Tianin FLD Technical Co.,Ltd. This is an online store providing Sensors at wholesale prices for consumers. You can call us or send enquiry, we would give you the prices, packing,deliverty and more detailed information on the E2EH We cooperate with DHL,TNT,FEDEX,UPS,EMS,etc.They guarantee to meet your needs in terms of time and money,even if you need your OMRON E2EHSensors tomorrow morning (aka overnight or next day air) on your desk, 2, 3 days or more.Note to international customers, YES, we ship worldwide.

A4E Enabling Switch/Features

ZUV Series Smart Curing System (Standard model/Multi-function model)/Features

WS02-CFSC1-E Network Configurator/Features

G9SA-300-SC Safety Relay Unit (Sensor Connector Type)/Features

NX-HAD[][][] NX-series High-speed Analog Input Unit/Features

OMRON E2EH lineup

E2EH Proximity Sensor Ideal for High Temperatures and Cleaning Processes/Lineuplast update: September 24, 2012

Sensors

Pre-wired Models

| Appearance | Sensing distance | Output configuration | Operation mode: NO | Operation mode: NC | |

|---|---|---|---|---|---|

| M12 | 3 mm | DC 2-wire (polarity) | E2EH-X3D1 2M | E2EH-X3D2 2M |

| DC 2-wire (no polarity) * | E2EH-X3D1-T 2M | --- | |||

| DC 3-wire (PNP) | E2EH-X3B1 2M | E2EH-X3B2 2M | |||

| DC 3-wire (NPN) | E2EH-X3C1 2M | E2EH-X3C2 2M | |||

| M18 | 7 mm | DC 2-wire (polarity) | E2EH-X7D1 2M | E2EH-X7D2 2M | |

| DC 2-wire (no polarity) * | E2EH-X7D1-T 2M | --- | |||

| DC 3-wire (PNP) | E2EH-X7B1 2M | E2EH-X7B2 2M | |||

| DC 3-wire (NPN) | E2EH-X7C1 2M | E2EH-X7C2 2M | |||

| M30 | 12 mm | DC 2-wire (polarity) | E2EH-X12D1 2M | E2EH-X12D2 2M | |

| DC 2-wire (no polarity) * | E2EH-X12D1-T 2M | --- | |||

| DC 3-wire (PNP) | E2EH-X12B1 2M | E2EH-X12B2 2M | |||

| DC 3-wire (NPN) | E2EH-X12C1 2M | E2EH-X12C2 2M | |||

Connector Models (M12)

| Appearance | Sensing distance | Output configuration | Operation mode: NO | Operation mode: NC | |

|---|---|---|---|---|---|

| M12 | 3 mm | DC 2-wire (polarity) | E2EH-X3D1-M1G | E2EH-X3D2-M1G |

| DC 3-wire (PNP) | E2EH-X3B1-M1 | E2EH-X3B2-M1 | |||

| DC 3-wire (NPN) | E2EH-X3C1-M1 | E2EH-X3C2-M1 | |||

| M18 | 7 mm | DC 2-wire (polarity) | E2EH-X7D1-M1G | E2EH-X7D2-M1G | |

| DC 3-wire (PNP) | E2EH-X7B1-M1 | E2EH-X7B2-M1 | |||

| DC 3-wire (NPN) | E2EH-X7C1-M1 | E2EH-X7C2-M1 | |||

| M30 | 12 mm | DC 2-wire (polarity) | E2EH-X12D1-M1G | E2EH-X12D2-M1G | |

| DC 3-wire (PNP) | E2EH-X12B1-M1 | E2EH-X12B2-M1 | |||

| DC 3-wire (NPN) | E2EH-X12C1-M1 | E2EH-X12C2-M1 | |||

* When using a no-polarity model, there is no need to be concerned about whether to connect to the positive or negative

side of the power supply. The load can be connected to either the +V side or 0 V side.

Accessories (Order Separately)

Sensor I/O Connectors (M12, Sockets on One Cable End)

(Models for Connectors: A Connector is not provided with the Sensor. Be sure to order a Connector separately.)

| Appearance | Cable length | Sensor I/O Connector model | Applicable Proximity Sensors | |

|---|---|---|---|---|

| Straight |  | 2 m | XS2F-E421-D80-E | E2EH-X[]D[]-M1G E2EH-X[]B[]-M1 E2EH-X[]C[]-M1 |

| 5 m | XS2F-E421-G80-E | |||

| L-shape |  | 2 m | XS2F-E422-D80-E | |

| 5 m | XS2F-E422-G80-E | |||

Note: The above Connectors conform to DIN40050-9 standard, provide IP69K protection, have a maximum operating

temperature of 105°C, and use SUS316L stainless steel.

last update: September 24, 2012

OMRON E2EH catalog

E2EH Proximity Sensor Ideal for High Temperatures and Cleaning Processes/Catalog- Catalog

- Manual

- CAD

English

Global Edition

| Catalog Name | Catalog Number [size] | Last Update | |

|---|---|---|---|

| | - [1531KB] | Oct 14, 201420141014 | E2EH Data Sheet |

OMRON E2EH dimension

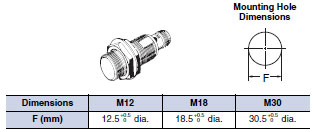

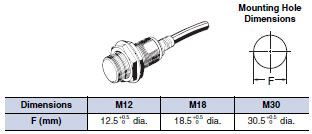

E2EH Proximity Sensor Ideal for High Temperatures and Cleaning Processes/Dimensionslast update: November 11, 2013

Tolerance class IT16 applies to dimensions in this data sheet unless otherwise specified.

Pre-wired Models (Shielded)

Connector Models (Shielded)

E2EH-X3[][]

![E2EH Dimensions 4 E2EH-X3[][]_Dim](/images/8767/e2eh_dm_325-107432.jpg)

E2EH-X3[][]-M1[]

![E2EH Dimensions 5 E2EH-X3[][]-M1[]_Dim](/images/8767/e2eh_dm_425-107434.jpg)

E2EH-X7[][]

![E2EH Dimensions 7 E2EH-X7[][]_Dim](/images/8767/e2eh_dm_525-107436.jpg)

E2EH-X7[][]-M1[]

![E2EH Dimensions 8 E2EH-X7[][]-M1[]_Dim](/images/8767/e2eh_dm_625-107437.jpg)

E2EH-X12[][]

![E2EH Dimensions 10 E2EH-X12[][]-M1[]_Dim](/images/8767/e2eh_dm_825-107439.jpg)

E2EH-X12[][]-M1[]

![E2EH Dimensions 11 E2EH-X12[][]_Dim](/images/8767/e2eh_dm_725-107441.jpg)

last update: November 11, 2013

OMRON E2EH specification

E2EH Proximity Sensor Ideal for High Temperatures and Cleaning Processes/Specificationslast update: September 23, 2012

E2EH-X[]D[] DC 2-Wire Models

| Size Shielded Model | M12 | M18 | M30 | |

|---|---|---|---|---|

| Shielded | ||||

| E2EH-X3D[] | E2EH-X7D[] | E2EH-X12D[] | ||

| Sensing distance | 3 mm | 7 mm | 12 mm | |

| Set distance *1 | 0 to 2.4 mm | 0 to 5.6 mm | 0 to 9.6 mm | |

| Differential travel | 15% max. of sensing distance | |||

| Detectable object | Ferrous metal (The sensing distance decreases with non-ferrous metal. Refer to Datasheet.) | |||

| Standard sensing object | Iron, 12 × 12 × 1 mm | Iron 21 × 21 × 1 mm | Iron 36 × 36 × 1 mm | |

| Response frequency *2 | 500 Hz | 300 Hz | 100 Hz | |

| Power supply voltage (operating voltage range) | 12 to 24 VDC, ripple (p-p): 10% max. (10 to 32 VDC, however, 24 VDC max. at temperatures over 100 ° C) | |||

| Leakage current | 0.8 mA max. | |||

| Control output | Load current | 3 to 100 mA (however, 3 to 50 mA at 100 to 110 ° C) | ||

| Residual voltage *3 | Polarity Models: 3 V max. No polarity Models: E2EH-X[]D[]-T : (5 V max. *3 (Load current: 100 mA, Cable length 2 m) | |||

| Indicators | D1 Models: Operation indicator (red), Setting indicator (yellow) D2 Models: Operation indicator (yellow) | |||

| Operation mode (with sensing object approaching) | D1 Models: NO D2 Models: NC Refer to Datasheet. | |||

| Protection circuits | Surge suppressor, Load short-circuit protection | |||

| Ambient temperature range | Operating: 0 to 100 ° C (0 to 110 ° C 1,000 h) *4 Storage: - 25 to 70 ° (with no icing or condensation) | |||

| Ambient humidity range | 35% to 95% | |||

| Temperature influence | ± 10% max. of sensing distance at 23 ° C in the temperature range of 0 to 70 ° C. ± 15% max. of sensing distance at 23 ° C in the temperature range of 70 to 100 ° C. - 15% to +20% of sensing distance at 23 ° C in the temperature range of 100 to 110 ° C. | |||

| Voltage influence | ± 10% max. of sensing distance at rated voltage in the 15% rated voltage range. | |||

| Insulation resistance | 50 M Ω min. (at 500 VDC) between current-carrying parts and case | |||

| Dielectric strength | 1,000 VAC, 50/60 Hz for 1 min between current-carrying parts and case | |||

| Vibration resistance | Destruction: 10 to 55 Hz 1.5-mm double amplitude for 2 hours each in X, Y and Z directions | |||

| Shock resistance | Destruction: 1,000 m/s2, 10 times each in X, Y and Z directions | |||

| Degree of protection | IEC IP67, DIN 40050-9 IP69K *5 | |||

| Connection method | Pre-wired Models (Standard cable length 2 m), Connector Models | |||

| Weight (packed state) | Pre-wired Models | Approx. 80 g | Approx. 145 g | Approx. 220 g |

| Connector Models | Approx. 30 g | Approx. 55 g | Approx. 125 g | |

| Materials | Case, clamping nut | Stainless steel (SUS316L) | ||

| Sensing surface | PBT | |||

| Cable | Heat-resistant PVC cable (Pre-wired model) | |||

| Accessories | Instruction manual | |||

*1. Use the yellow indicator on D1 Models as a guide.

*2. The response frequency is an average value.

Measurement conditions are as follows: standard sensing object, a distance of twice the standard sensing object,

and a set distance of half the sensing distance.

*3. The residual voltage of each E2EH-X[]D[] DC 2-Wire Model is 5 V. When connecting to a device, make sure that the

device can withstand the residual voltage. (Refer to Data Sheet.)

*4. Operation with power supplied for 1,000 h has been verified at 110°C. Do not bend the cable repeatedly at 100°C or

higher.

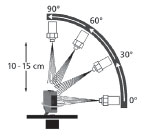

*5. IP69K Degree of Protection Specification

IP69K is a protection standard against high temperature and high-pressure water defined in the German standard

DIN 40050, Part 9. The test piece is sprayed with water at 80°C at a water pressure of 80 to 100 BAR using a

specified nozzle shape at a rate of 14 to 16 liters/min.

The distance between the test piece and nozzle is 10 to 15 cm, and water is sprayed horizontally for 30 seconds each

at 0°, 30°, 60°, and 90° while rotating the test piece on a horizontal plane.

E2EH-X[]C[]/B[] DC 3-Wire Models

| Size Shielded Model | M12 | M18 | M30 | |

|---|---|---|---|---|

| Shielded | ||||

| E2EH-X3C[]/B[] | E2EH-X7C[]/B[] | E2EH-X12C[]/B[] | ||

| Sensing distance | 3 mm±10% | 7 mm±10% | 12 mm±10% | |

| Set distance *1 | 0 to 2.4 mm | 0 to 5.6 mm | 0 to 9.6 mm | |

| Differential travel | 15% max. of sensing distance | |||

| Detectable object | Ferrous metal (The sensing distance decreases with non-ferrous metal. Refer to Datasheet.) | |||

| Standard sensing object | Iron, 12 × 12 × 1 mm | Iron 21 × 21 × 1 mm | Iron 36 × 36 × 1 mm | |

| Response frequency *2 | 500 Hz | 300 Hz | 100 Hz | |

| Power supply voltage (operating voltage range) | 12 to 24 VDC, ripple (p-p): 10% max. (10 to 32 VDC, however, 24 VDC max. at temperatures over 100 ° C) | |||

| Current consumption | 10 mA max. | |||

| Control output | Load current | 100 mA max. (however, 50 mA max. at 100 to 120 ° C) | ||

| Residual voltage | 2 V max. (Load current: 100 mA, Cable length 2 m) | |||

| Indicators | Operation indicator (yellow) | |||

| Operating mode (with sensing object approaching) | C1 Models: NO C2 Models: NC B1 Models: NO B2 Models: NC Refer to Datasheet. | |||

| Protection circuits | Power supply reverse polarity protection, Surge suppressor, Load short-circuit protection, Reversed output polarity protection | |||

| Ambient temperature range | Operating: 0 to 100 ° C (0 to 120 ° C 1,000 h) *2 Storage: - 25 to 70 ° C (with no icing or condensation) | |||

| Ambient humidity range | 35% to 95% | |||

| Temperature influence | ± 10% max. of sensing distance at 23 ° C in the temperature range of 0 to 70 ° C. ± 15% max. of sensing distance at 23 ° C in the temperature range of 70 to 100 ° C. - 15% to 20% of sensing distance at 23 ° C in the temperature range of 100 to 120 ° C. | |||

| Voltage influence | 10% max. of sensing distance at rated voltage in the 15% rated voltage range. | |||

| Insulation resistance | 50 M Ω min. (at 500 VDC) between current-carrying parts and case | |||

| Dielectric strength | 1,000 VAC, 50/60 Hz for 1 min between current-carrying parts and case | |||

| Vibration resistance | Destruction: 10 to 55 Hz 1.5-mm double amplitude for 2 hours each in X, Y and Z directions | |||

| Shock resistance | Destruction: 1,000 m/s2, 10 times each in X, Y and Z directions | |||

| Degree of protection | IEC IP67, DIN 40050-9 IP69K | |||

| Connection method | Pre-wired Models (Standard cable length 2 m), Connector Models | |||

| Weight (packed state) | Pre-wired Models | Approx. 80 g | Approx. 145 g | Approx. 220 g |

| Connector Models | Approx. 30 g | Approx. 55 g | Approx. 125 g | |

| Materials | Case, clamping nut | Stainless steel (SUS316L) | ||

| Sensing surface | PBT | |||

| Cable | Heat-resistant PVC cable (Pre-wired Model) | |||

| Accessories | Instruction manual | |||

*1. The response frequency is an average value.

Measurement conditions are as follows: standard sensing object, a distance of twice the standard sensing object,

and a set distance of half the sensing distance.

*2. Operation with power supplied for 1,000 h has been verified at 120°C. Do not bend the cable repeatedly at 100°C or

higher.

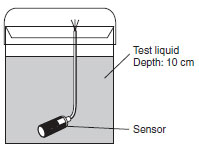

Resistance to Detergents, Disinfectants, and Chemicals

- Performance is assured for typical detergents and disinfectants, but performance may not be maintained for some detergents and disinfectants. Refer to the following table when using these agents.

- The E2EH passed testing for resistance to detergents and disinfectants performed using the items in the following table. Refer to this table when considering use of detergents and disinfectants.

| Category | Product name | Concentration | Temperature | Time |

|---|---|---|---|---|

| Chemical | Sodium hydroxide (NaOH) | 1.5% | 70 ° C | 240h |

| Potassium hydroxide (KOH) | 1.5% | 70 ° C | 240h | |

| Phosphoric acid (H3PO4) | 2.5% | 70 ° C | 240h | |

| Sodium hypochlorite (NaClO) | 0.3% | 25 ° C | 240h | |

| Hydrogen peroxide (H2O2) | 6.5% | 25 ° C | 240h | |

| Alkaline foam detergent | P3-topax-66s (Manufactured by Ecolab) | 3.0% | 70 ° C | 240h |

| Acidic foam detergent | P3-topax-56 (Manufactured by Ecolab) | 5.0% | 70 ° C | 240h |

| Disinfectant | P3-oxonia active 90 (Manufactured by Ecolab) | 1.0% | 25 ° C | 240h |

Test Conditions

After the test is completed, check that no problems exist with the following product characteristics.

(1) Appearance (no damage that will affect the product characteristics)

(2) Operation Check (ON/OFF)

(3) Insulation resistance: 50 MΩ min. (at 500 VDC)

(4) Dielectric strength (1,000 VAC for 1 minute)

(5) Water resistance (IP67)

last update: September 23, 2012

- NO. E2EH

- TYPE:Proximity Sensors Cylindrical

Copyright Statement

Copyright Statement - DATE:2021-06-11

- Associated products:

E2FM Proximity Sensor with All-stainless Housing/Features E2FQ Chemical-resistant Proximity Sensor/Features