OMRON CS1W-EIP21Automation Systems/ Programmable Controllers/CS1

OMRON CS1W-EIP21 Automation Systems

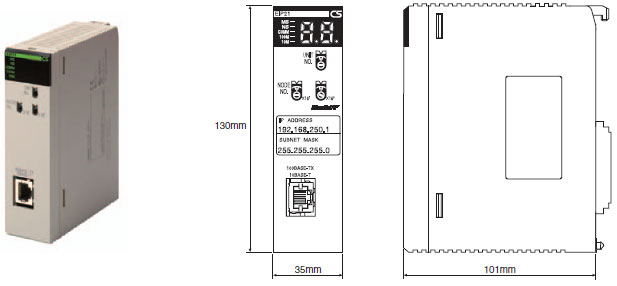

OMRON CS1W-EIP21 Dimensions

/Images/l_1994-25-118629-198x198.jpglast update: October 11, 2016

Global Standard

Highly Open Global Standard for FA Industry with High Future Potential

The ODVA promotes the spread of Industrial Ethernet all over the world.

EtherNet/IP can be used to communicate with many devices from various companies around the world in addition to OMRON components (such as Temperature Controllers and Sensors). The use of EtherNet/IP will rapidly increase the development of an EtherNet/IP multivendor environment (including robots and safety devices).

Integrated Information and Control Network

Seamless communications on the control line and information monitoring line with EtherNet/IP

Using the global standard open protocol (CIP), an independent network system can be created with seamless data flow between the control line and the information monitoring line.

OMRON FINS message communications can also be used on the same network because it is a standard LAN.

Improved operation efficiency with common Support Software operation

Use the same operating procedures for both EtherNet/IP and DeviceNet Support Software.

The same Support Software procedures can be used from a remote location for device configuration, monitoring, and program transfer for the DeviceNet and EtherNet/IP networks.

Monitor Safety Systems

Safety systems can be monitored through the EtherNet/IP.

The safety system can be monitored from a PLC by using a modular designed Safety Control Unit with a EtherNet/IP Coupler Unit.

Convenience of the Universal Ethernet Right in Your Hands

Higher Data Link Capacity (9 times the capacity of previous OMRON models)

High-capacity communications with high-speed high-capacity bus

All types of data, from process interlocks and manufacturing recipes to production data, can be exchanged at high speed and with optimal timing. The ability to communicate is incomparably better than previous networks, such as the Controller Link and FL-net.

Note: Using a built-in EtherNet/IP port on CJ2H and EtherNet/IP Units.

Low Cost Expansion for Each Line

Flexible topology with the Ethernet switch

Flexible wiring and expansion are possible with Ethernet switches. This means that there will be no total network crashes caused by communications path errors, ensuring high network performance and security.

- Joining and leaving the network is possible during communications.

Nodes can leave the network during operation, enabling easy maintenance for error detection, separation, and restoration.

- Unpredictable delays caused by data collisions are minimum.

- Problems caused by wiring errors are minimized to each line.

Star topology using Ethernet switch technology

Reduced Network Facility and Wiring Costs

Generic LAN cables can be used.

- Metal cables of category 5, 5e, or higher can be used as LAN cables.

- Generic RJ-45 connectors can be used.

Standard wireless LAN can be used because EtherNet/IP is also Universal Ethernet.

There is no need to rewire even when layout has been changed.

- EtherNet/IP can be made wireless using the standard wireless LAN.

- High-speed Smart Roaming communications can be used for mobile units with the WE70 FA Wireless LAN. The communications range can be expanded by relaying communications between access points.

Integration of Control and Information Networks

High-speed Data Links with Optimal Cycles for Applications (30 times higher than previous OMRON models)

Flexible and high-speed cyclic communications

- Grouping can be used in data link tables to create multiple sections.

Data link table can be divided into up to 256 groups (= connections).

The optimum communications cycle for the application can be set for each group.

- Cyclic synchronization can be set for each group.

The communications cycle can be set to between 0.5 ms and 10 s in 0.5-ms increments. Data concurrency is maintained for each connection. The communications cycle does not change even if the number of nodes increases. The communications performance is 30 times better than that of the Controller Link.

Example:

Data link refresh cycle for 25 linked Unit and 20,000 words/network is reduced from 300 ms to 10 ms.

- Facilities can be easily expanded.

When expanding facilities, all you need to do is make additions to the tables. Expansion is possible with little time and low cost.

Note: Using a built-in EtherNet/IP port on CJ2H and EtherNet/IP Units.

FTP, Data Links, and Support Software Can Be Used Simultaneously with One Port

With the multipurpose EtherNet/IP port, an Ethernet Unit is not required for expansion.

Using the multipurpose EtherNet/IP port built into a CJ/NJ/NX/NY CPU Unit, a single port can be used for data link communications between PLCs, messages between PLCs, and Universal Ethernet communications, such as FTP transfers while connecting Support Software. An EtherNet/IP Unit can be added to any CS/CJ-series PLC to achieve the same functions.

Memory Map Management Becomes Unnecessary.

Freed from memory map by tags

The transmission/reception area can be specified with normal names called tag names instead of addresses for communication on data links between devices or when communication with the host application.

The efficiency of design, startup, maintenance, and upgrading are improved.

- PT and host applications can be developed in parallel.

Network symbols defined in CJ/NJ/NX/NY CPU Units can be used as tags when designing the PT screen.

Design is easy: Just decide on the tag names for the information and control departments.

Changes to allocated addresses is not needed later in development.

- Easier facility upgrading and maintenance

Even if physical addresses change in the PLC, there is no need to make any changes in the data link settings, in the PT, or in the host application.

last update: October 11, 2016

Purchase the OMRON CS1 Please fill in the following

If you have just landed here, this product OMRON CS1W-EIP21 Automation Systems,Automation Systems is offered online by Tianin FLD Technical Co.,Ltd. This is an online store providing Automation Systems at wholesale prices for consumers. You can call us or send enquiry, we would give you the prices, packing,deliverty and more detailed information on the CS1W-EIP21 We cooperate with DHL,TNT,FEDEX,UPS,EMS,etc.They guarantee to meet your needs in terms of time and money,even if you need your OMRON CS1W-EIP21Automation Systems tomorrow morning (aka overnight or next day air) on your desk, 2, 3 days or more.Note to international customers, YES, we ship worldwide.

ZG2 Smart Sensor (2D Measurement Sensor)/Features

A16 Pushbutton Switch (Detachable) (Lighted/Non-Lighted) (Cylindrical 16-dia.)/Features

A30NK Key-type Selector Switches/Features

H3RN Solid-state Timer/Features

NX-TS NX-series Temperature Input Unit/Features

OMRON CS1W-EIP21 dimension

CS1W-EIP21 CS-series EtherNet/IP Unit/Dimensionslast update: November 12, 2012

CS1W-EIP21

last update: November 12, 2012

OMRON CS1W-EIP21 lineup

CS1W-EIP21 CS-series EtherNet/IP Unit/Lineuplast update: July 08, 2015

International Standards

- The standards are abbreviated as follows: U: UL, U1: UL (Class I Division 2 Products for Hazardous Locations), C: CSA, UC: cULus, UC1: cULus (Class I Division 2 Products for Hazardous Locations), CU: cUL, N: NK, L: Lloyd, and CE: EC Directives.

- Contact your OMRON representative for further details and applicable conditions for these standards.

EtherNet/IP Unit

| Unit type | Product name | Specifications | No. of unit numbers allocated | Current consump- tion (A) | Model | Stand- ards | |||

|---|---|---|---|---|---|---|---|---|---|

| Communi- cations cable | Communi- cations functions | Units per CPU Unit | 5 V sys- tem | 24 V sys- tem | |||||

| CS1 CPU Bus Unit | EtherNet/IP Unit  | Shielded twisted- pair (STP) cable Categories: 100 Ω at 5, 5e | Tag Data Link Functions, Message Communications Functions | 8 max. | 1 | 0.41 | --- | CS1W-EIP21 | UC1, N, L, CE |

Industrial Switching Hubs

| Product name | Appearance | Specifications | Accessories | Current consump- tion (A) | Model | Stand- ards | ||

|---|---|---|---|---|---|---|---|---|

| Functions | No. of pors | Failure detec- tion | ||||||

| Industrial Switching Hubs |  | Quality of Service (QoS): EtherNet/IP control data priority Failure detection: Broadcast storm and LSI error detection 10/100BASE-TX, Auto-Negotiation | 3 | No | Power supply connector | 0.22 | W4S1-03B | UC, CE |

| 5 | No | 0.22 | W4S1-05B | ||||

| 5 | Yes | Power supply connector Connector for informing error | 0.22 | W4S1-05C | CE | |||

last update: July 08, 2015

OMRON CS1W-EIP21 catalog

CS1W-EIP21 CS-series EtherNet/IP Unit/Catalog- Catalog

- Manual

- CAD

English

Global Edition

| Catalog Name | Catalog Number [size] | Last Update | |

|---|---|---|---|

| | - [652KB] | Apr 03, 201720170403 | CS1W-EIP21 Data Sheet |

| | R150-E1-16 [2968KB] | Sep 03, 201820180903 | EtherNet/IP™ Catalog |

OMRON CS1W-EIP21 specification

CS1W-EIP21 CS-series EtherNet/IP Unit/Specificationslast update: April 3, 2017

EtherNet/IP Unit Specifications

| Item | Specifications | |

|---|---|---|

| Model number | CS1W-EIP21 | |

| Type | 100Base-TX (See note.) | |

| Applicable PLCs | CS-series PLCs | |

| Unit classification | CS-series CPU Bus Unit | |

| Mounting location | CPU Rack or Expansion Rack | |

| Number of Units that can be mounted | 8 max. (including Expansion Racks) | |

| CPU Unit words used | Allocated CIO Area words (CPU Bus Unit words) | 25 words/Unit (one unit number's words) |

| These words contain control bits and flags, the target node PLC's operating and error information, Unit status, communications status, registered/normal target node information, and FINS/TCP connection status. | ||

| Allocated DM Area words (CPU Bus Unit words) | 100 words/Unit (one unit number's words) | |

| These words contain the IP address display/setting area | ||

| User-set area | Any usable data area words | |

| Target node PLC's operating and error information, and registered/normal target node information | ||

| CPU Bus Unit System Setup | Not used. | |

| Non-volatile memory within EtherNet/IP Unit (See note.) | The following settings are stored in the EtherNet/IP Unit's non-volatile memory. Note: Unlike the regular Ethernet Units, the CPU Bus Unit Setup Area in the CPU Unit is not used for these settings. 1. Unit setup (communications settings for the EtherNet/IP Unit, such as the IP address, DNS server settings, host name, baud rate, FINS/UDP settings, and FINS/TCP settings) 2. Tag data link settings (device parameters) | |

| Transfer specifications | Media access method | CSMA/CD |

| Modulation method | Baseband | |

| Transmission paths | Star form | |

| Baud rate | 100 Mbit/s (100Base-TX) | |

| Transmission media | Shielded twisted-pair (STP) cable Categories: 100 Ω at 5, 5e | |

| Transmission distance | 100 m (distance between hub and node) | |

| Number of cascade connections | There is no limitation when a switching hub is used. | |

| Current consumption (Unit) | 410 mA max. at 5 V DC | |

| Weight | 171 g max. | |

| Dimensions | 35 × 130 × 101 mm (W × H × D) | |

| Other general specifications | Other specifications conform to the general specifications of the CS-series | |

Note: If tag data links are being used, use 100Base-TX. Otherwise, 10Base-T can be used, but this is not recommended.

Communications Specifications

| Item | Specifications | ||

|---|---|---|---|

| CIP service | Tag data links (Cyclic communi- cations) | Number of connections | 256 |

| Packet interval (refresh cycle) | 0.5 to 10,000 ms (in 0.5-ms units) Can be set independently for each connection. (Data is refreshed over the network at the preset interval and does not depend on the number of nodes.) | ||

| Maximum allowed communications bandwidth per Unit | 6,000 to 12,000 pps *1 *2 | ||

| Number of tag sets | 256 | ||

| Tag types | CIO Area, DM Area, EM Area, Holding Area, and Work Area | ||

| Number of tags per connection (= 1 tag set) | 8 (7 tags when the tag set contains the PLC status) | ||

| Maximum link data size per node | 184,832 words | ||

| Maximum data size per connection | 252 words or 722 words *3 Note: Data synchronicity is maintained within each connection. | ||

| Number of registrable tag sets | 256 (1 connection = 1 tag set) | ||

| Maximum size of 1 tag set | 722 words (The PLC status uses 1 word when the tag set contains the PLC status.) | ||

| Maximum number of tags that can be refreshed per CPU Unit cycle *4 | Output/Transmission (CPU to EtherNet/IP): 19 Input/Reception (EtherNet/IP to CPU): 20 *5 | ||

| Data that can be refreshed per CPU Unit cycle *4 | Output/Transmission (CPU to EtherNet/IP): 7,405 words Input/Reception (EtherNet/IP to CPU): 7,405 words | ||

| Changing tag data link parameters during operation | Supported *6 | ||

| Multicast packet filter function *7 | Supported | ||

| Explicit messaging | Class 3 (connected) | Number of connections: 128 | |

| UCMM (unconnected) | Number of clients that can communicate at one time: 32 max. Number of servers that can communicate at one time: 32 max. | ||

| CIP routing | CS1W-EIP21, CJ1W-EIP21, CJ2H-CPU6[]-EIP, CJ2M-CPU3[] | ||

| FINS service | FINS/UDP | Supported | |

| FINS/TCP | 16 connections max. | ||

| EtherNet/IP conformance test | Conforms to A5 | ||

| Ethernet interface | 10BASE-T or 100BASE-TX Auto Negotiation or fixed settings | ||

*1. In this case, pps means "packets per second" and indicates the number of packets that can be processed in one

second.

*2. To use 505 to 1,444 bytes as the data size, the system must support the Large Forward Open standard (an optional

CIP specification). The CS/CJ-series Units support this standard, but before connecting to nodes of other companies,

confirm that those devices also support it.

*3. If the maximum data size is exceeded, the data refreshing with the CPU Unit will extend over two or more cycles.

*4. If status layout is selected in the user settings, the maximum number of tags that can be received is 19 tags.

*5. If parameters are changed in the EtherNet/IP Unit, however, the EtherNet/IP Unit will be restarted. When other nodes

are communicating with the affected node, the communications will temporarily time out and automatically recover

later.

*6. Because the EtherNet/IP Unit is equipped with an IGMP client, unnecessary multicast packets can be filtered by using

a switching hub that supports IGMP snooping.

*7. The EtherNet/IP Unit uses the TCP/UDP port numbers shown in the following table.

| Service | Protocol | Port number | Remarks |

|---|---|---|---|

| Tag data links | UDP | 2222 | Fixed value |

| Class 3, UCMM | TCP/UDP | 44818 | |

| DNS | UDP | 53 | |

| FINS/UDP service | UDP | 9600 | Port numbers in the Unit Setup can be changed with the CX-Programmer. |

| FINS/TCP service | TCP | 9600 | |

| FTP | TCP | 20, 21 | |

| SNTP | UDP | 123 | |

| SNMP | UDP | 161 | |

| SNMP trap | UDP | 162 |

Network Configurator Requirements

The Network Configurator Ver. 3.0 or higher is a software package designed for building, setting, and controlling a multi-vendor EtherNet/IP Network using OMRON's EtherNet/IP. It is included in CX-One. The Network Configurator provides the following functions for building, setting, and controlling EtherNet/IP.

| Item | Specification | ||

|---|---|---|---|

| Operating environment | CXONE-AL[][]D-V[] | ||

| Network connection method | CS1/CJ1 | CJ2 | |

| Serial interface | CPU Unit's Peripheral or RS-232C port | CPU Unit's USB or RS-232C port | |

| Ethernet interface | EtherNet/IP Unit's Ethernet port | CPU Unit's Ethernet port EtherNet/IP Unit's Ethernet port | |

| Location on Network | A single node address is used (only when directly connected to EtherNet/IP). | ||

| Number of Units that can be connected to Network | A single Network Configurator per Network (More than one Configurator cannot be used in the same system.) | ||

| Main functions | Network control functions | The Network configuration can be created and edited regardless of whether the Network Configurator is online or offline. The Network configuration can be read from a file or the network. | |

| Configuration functions | The EDS files used by the Network Configurator can be installed and deleted. | ||

| Supported file formats | Configurator network configuration files (*.ncf) Configuration files (*.ncf) created using the Network Configurator for EtherNet/IP (version 2) can be imported by selecting External Data - Import from the File Menu. | ||

last update: April 3, 2017

- NO. CS1W-EIP21

- TYPE:Programmable Controllers CS1 CPU Bus Units

- DATE:2021-06-08

- Associated products:

CJ1W-EIP21 CJ-series EtherNet/IP Unit/Features CJ2H-CPU6[]-EIP CJ-series CJ2H (Built-in EtherNet/IP) CPU Units/Features